Furniture Design & Woodworking

Code: W05W01-21

-

II

Level II

Students have experience working with computer-aided design with basic principles of CAM/software.

-

III

Level III

Students have some formal training in digital fabrication, experience with a variety of materials and fabrication processes, and know how to use CNC, 3-D printers, or laser cutters competently and safely. Students have a portfolio of their work.

-

IV

Level IV

Students have advanced skill and knowledge of digital fabrication and have experience with a variety of materials and fabrication processes, and know how to use CNC, 3-D printers, or laser cutters competently and safely. Students are highly motivated and have a portfolio of their artwork.

-

Virtual Workshop

Virtual Workshop, learn from the comfort of your own home.

VIRTUAL WORKSHOP

All About The CNC

Feb 1 - 18, 2021

Every Monday & Wednesday, 4- 5:30PM MST

Concept

Take your digital fabrication skills to a higher level in this advanced virtual workshop all about the CNC router. Demonstrations include design considerations for outputting to a 3-axis CNC, but the emphasis is placed on writing 2D and 3D toolpaths. Students learn everything from feeds and speeds, to bit selection, to 3-axis machine operation. This deep dive into the complex process of computer-aided machining (CAM) empowers participants to push their artistic practices into a new realm of fabrication. Previous CAD (computer-aided design) experience is necessary to enroll in this course. Though no specific software is required for CAD, we will use V-Carve Pro and Fusion 360 for toolpathing. The workshop culminates in a final project to be fabricated on the CNC routers at Anderson Ranch and mailed back to students with shipping and materials covered by the studio fee.

This workshop meets 4-5:30PM on Mondays and Wednesdays for group sessions, and 4-5:30PM for office hours. Please note that the first Tuesday only will be a group session, not office hours. Zoom Video Conferencing software (download free from Zoom.com) will be used to facilitate the class sessions. An Anderson Ranch staff member will coordinate the online platform. Further details will be emailed to registrants.

Media & Techniques

CAD, Fusion 360 CAM, V-Carve Pro, CNC router, plywood, MDF, blue foam

Faculty

Vincent Edwards

Vincent Edwards teaches digital fabrication and sculpture at the University of Arkansas where he runs the 3-D Advanced Technologies Lab. He received his MFA from the Herron School of Art and Design in 2012. Vincent’s studio practice focuses on hybrid methodologies, specifically the intersection of traditional furniture craft and digital fabrication.

System of Curves Bench

Workshop Details

Scholarships, College Credit & Discounts

Making Art Accessible

Applications for scholarship support are encouraged. Specific scholarships are funded by Ranch supporters, either through endowed funds or special gifts.

Many colleges and universities offer college credit for workshops taken at Anderson Ranch. Discounts are available for students and teachers.

You Might Also Be Interested In

-

III

Level III

Students have some formal training in 3-D design, experience with a variety of materials and fabrication processes, and know how to use machine and hand tools competently and safely. Students have a portfolio of their artwork.

-

IV

Level IV

Students have advanced skill and knowledge of furniture design. Students are highly motivated and have multiple portfolios of their artwork.

Jun 1 - 5, 2026

9 AM - 5 PM

CNC: A Designer's Tool

Jomo Tariku

Tuition $1,250

Code W0101-26

Delve into the world of computer numerically controlled (CNC) furniture part making in this introductory fabrication workshop. Technology has propelled contemporary design in countless unexpected ways throughout history, and this class considers the modernization of traditional furniture design across cultures. Participants are encouraged to explore their unique artistic voice as they design furniture parts such as legs, backrests, stretchers, and decorative elements on paper. We then translate them into Rhinoceros 3D through basic 2D computer-aided design and further modeling. Students are introduced to best practices in material preparation, CNC hold-down methods, tools, and supplies. Final parts are cut as double sided 3D elements on the CNC.

-

O

Open to All

Students of any skill and knowledge level.

Jun 8 - 12, 2026

9 AM - 5 PM

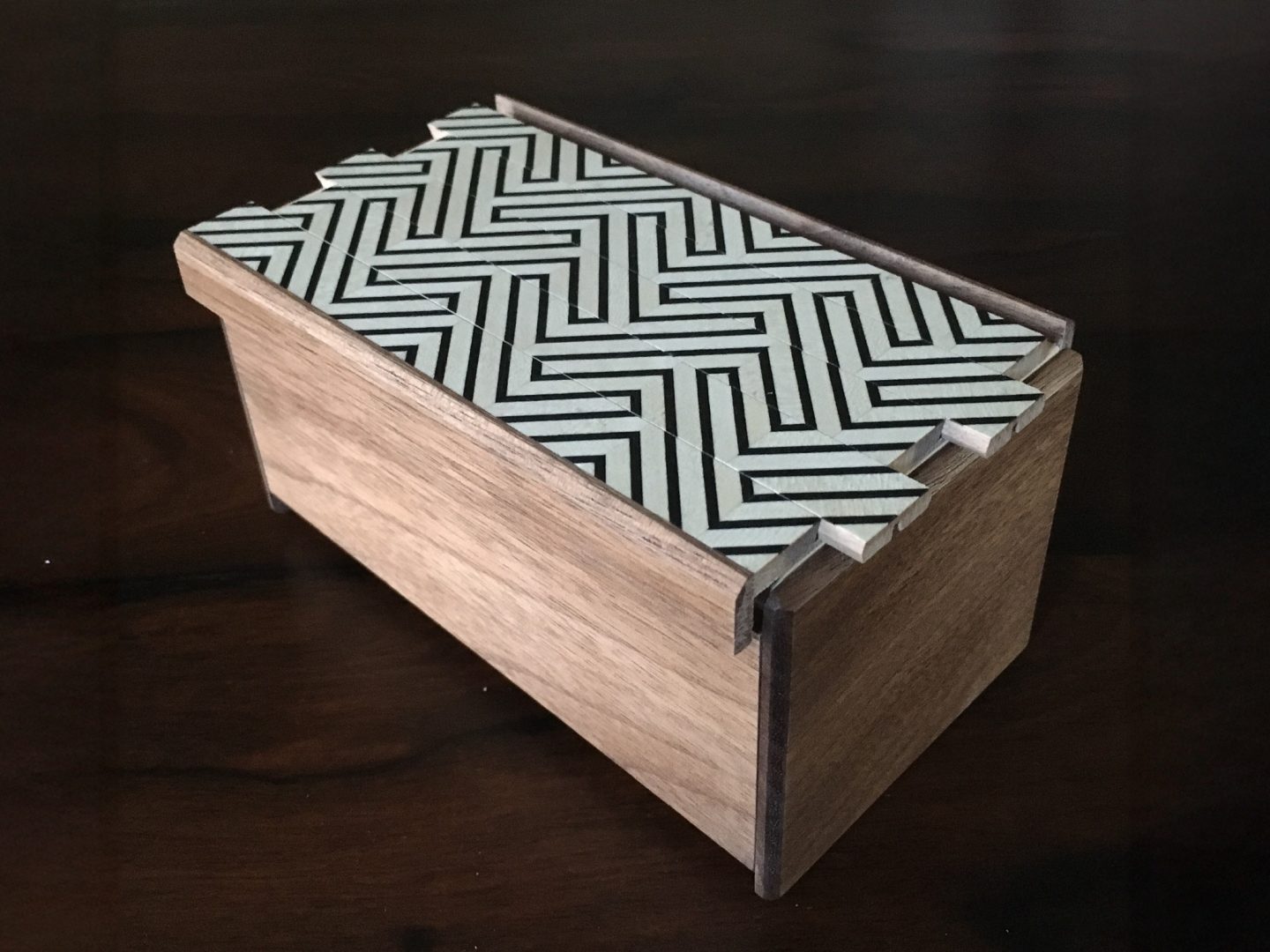

Making a Traditional Japanese Puzzle Box

Kagen Sound

Tuition $1,250

Code W0202-26

This unique and dynamic woodworking class explores the Japanese art of making secret opening boxes in three stages. Students begin by creating a box infrastructure, then cut plates of wood, which slide in a sequence and stay attached to the framework. Finally, the box is assembled and a finish is applied. After each student completes an initial warm-up puzzle box, they explore a number of other wooden mechanisms and decorative inlays meant to disguise and hide moving parts. Students are encouraged to design and build their own custom puzzle box variation, focusing primarily on hand tool use with the aid of miniature router table set-ups that assist in cutting notches for moving parts and joinery.

-

II

Level II

Students have experience working with stationary machines and power tools and are familiar with basic principles of joinery and 3-D design.

-

III

Level III

Students have some formal training in 3-D design, experience with a variety of materials and fabrication processes, and know how to use machine and hand tools competently and safely. Students have a portfolio of their artwork.

-

IV

Level IV

Students have advanced skill and knowledge of furniture design. Students are highly motivated and have multiple portfolios of their artwork.

Jun 15 - 19, 2026

9 AM - 5 PM

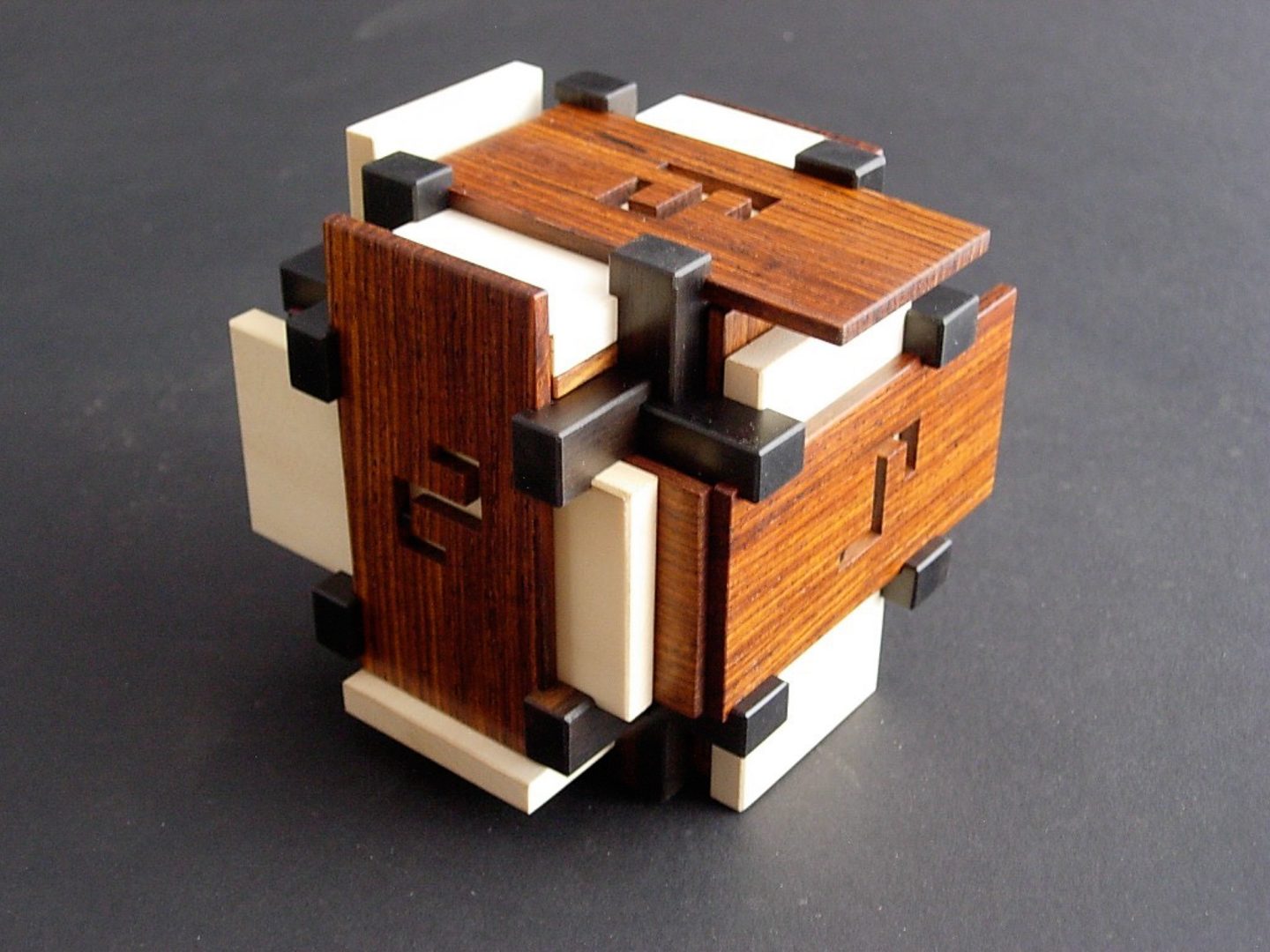

Advanced Puzzle Box Design: Designing and Fine-Tuning Mechanisms

Kagen Sound

Tuition $1,250

Code W0303-26

This class is open to students who have taken the basic puzzle box workshop and want to go further, dreaming up their own mechanism for a unique box. Students work with precut milled woods and have access to a variety of specific hardware like springs, magnets, and ball bearings to prototype a more thematic puzzle concept. Time is spent testing and making a puzzle mechanism work before moving towards building a box that is locked with a puzzle mechanism.